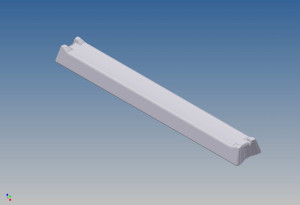

REMELT INGOT MINI CASTER LINES

The low volume mini ingot casting machines are designed for the production of secondary alloy ingots. This ingot casting machine retains the robust and reliable features which is synonymous with o.d.t. Engineering quality standards.

The “o.d.t. Mini Caster” can be supplied in modular form to cater for your current needs with the option to further automate the ingot production line as future demand increases:

A: Ingot casting machine (base offer) Optional Modular Equipment:

B: With secondary ingot cooling system attached to the production line downstream of the caster de-moulding area. This allows safe manual stacking of the ingots at the end of the production line

C: Automatic robotic ingot stacking machine attached to the production line downstream of the secondary ingot cooling system.

This allows automatic stacking of the ingots into suitable ingot stacks and includes the stack strapping station to form an ingot stack which is ready for safe transportation to your client.

Key Benefits of Remelt Ingot Mini Caster Lines:

- These casting machines are designed to cater for the production of ingots from 4 kg to 8 kg for the secondary alloy industry. The “o.d.t. Mini Caster “ is designed with the same philosophy of our large full scale machines in being manufactured for longevity to cope with the harsh industrial conditions in which they operate.

PRODUCT LINES