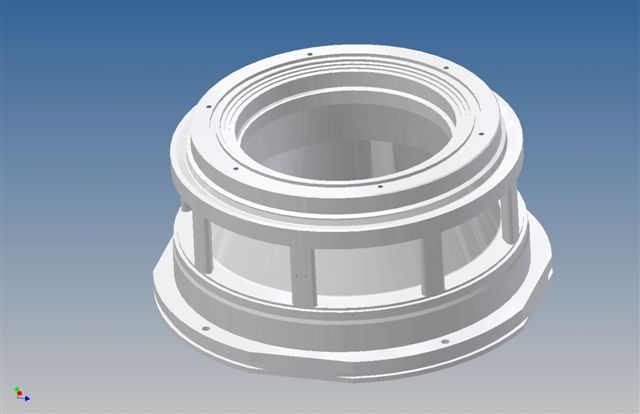

BILLET MOULD SYSTEMS

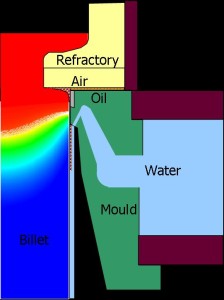

Billet Mould systems are designed and supplied in AirCAST Air Cushioned Moulds and traditional hot-top moulds for the production of extrusion billet. The o.d.t. AirCAST aluminium billet mould produces extrusion billet that is of high quality both inside and out. o.d.t. Engineering is able to supply a wide range of mould technology systems to suit the casting of aluminium billets, rolling ingots and T-bar.

Key Benefits of AirCAST Mould Systems in VDC

- designed and tested using scientific principles for optimum performance

- excellent surface quality

- segregation zone is minimal

- continuous lubrication

- no graphite ring required

- low operating costs

- low maintenance costs

- reduced billet cut-off

- high flexibility to produce various billet sizes

PRODUCT LINES